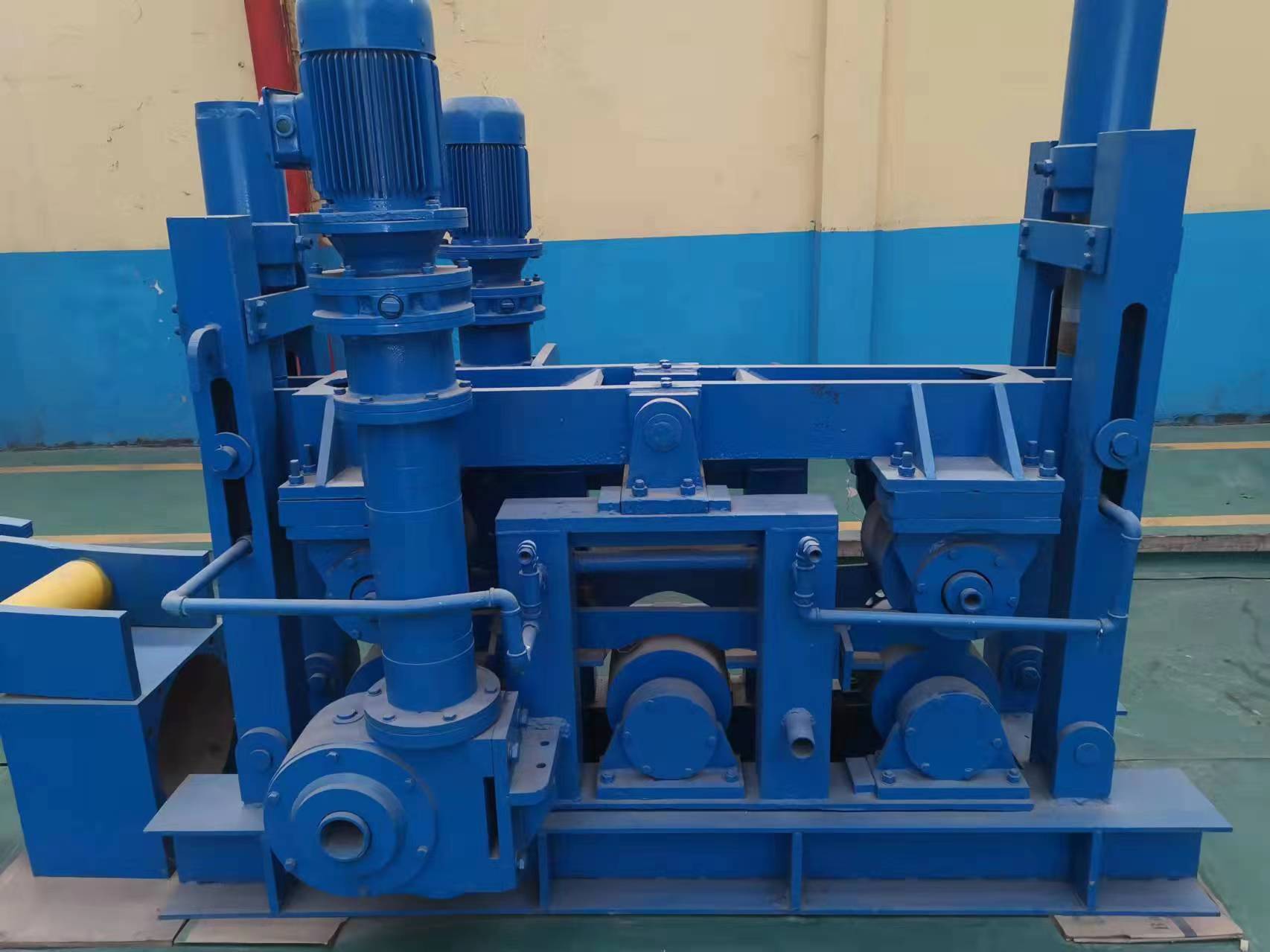

Withdrawal Straightener

Category:

Wechat:

008619339904886

WhatsApp:

+8618595836738

- DESCRIPTION

-

- Commodity name: Withdrawal Straightener

The company produces: rolling mill, hot rolling, cold rolling, section steel equipment (Angle steel, c steel, t steel, u steel, v steel, PI steel, flat steel, ball flat steel, etc.), bar production line (round steel, rebar), Hafen groove (also known as groove steel), hexagonal steel, pipe pile end plate, silicon steel sheet, silicon steel sheet, aluminum casting and rolling machine, aluminum plate rolling mill and other rolling equipment.

Mill auxiliary machinery: roller table, lifting platform, cold bed (automatic bar cold bed, steel cold bed), hot saw machine, push steel machine, straightening machine, flying shear and waste rebar reform equipment and intermediate frequency melting furnace, intermediate frequency high frequency heating equipment, available for users to choose.

In addition to supplying the domestic market, the products are also exported to Russia, Nigeria, Algeria, Egypt, Saudi Arabia, Uzbekistan, Kazakhstan, Fiji, Bangladesh and other countries and regions.

In the realm of industrial material processing, a new star has emerged - the Withdrawal Straightener. This innovative piece of equipment is set to transform the way many industries handle and prepare materials.

The Withdrawal Straightener is designed with a primary focus on achieving perfect straightness in materials. Whether it's metal rods, wires, or other long - shaped materials, this device plays a crucial role in ensuring that they are free from bends and curvatures. This is of utmost importance as it directly impacts the quality of the final products in which these materials are used.

One of the key features of the Withdrawal Straightener is its high - precision adjustment capabilities. Operators can finely tune the straightening process according to the specific requirements of different materials. For instance, for a relatively thin wire, the machine can be adjusted to apply just the right amount of force to straighten it without causing any damage. On the other hand, for thicker metal rods, it can be set to a more robust straightening mode.

Efficiency is another remarkable aspect of this product. The Withdrawal Straightener can process materials at a relatively high speed, which is a great advantage in large - scale industrial production. This not only helps in meeting tight production schedules but also in reducing overall production costs. By streamlining the straightening process, manufacturers can save both time and resources.

The construction of the Withdrawal Straightener is also worth noting. It is built with durable and high - quality components that ensure its long - term reliability. This means that maintenance requirements are relatively low, and the machine can withstand the rigors of continuous operation in industrial environments.

In addition, the user - friendly interface of the Withdrawal Straightener makes it accessible to operators with different levels of expertise. The controls are intuitive, allowing for easy setup and operation. This simplicity also reduces the training time required for new operators, enabling them to quickly get up to speed with the machine's functions.

The applications of the Withdrawal Straightener are widespread across various industries. In the construction industry, it is used to straighten steel bars before they are used in building structures. In the manufacturing of electrical components, it straightens wires to ensure proper functioning within the devices. In the automotive industry, it helps in preparing various metal parts for assembly.

In conclusion, the Withdrawal Straightener is a game - changer in the field of material processing. Its ability to precisely straighten materials, combined with its efficiency, durability, and user - friendly operation, makes it an invaluable asset for any industry that deals with long - shaped materials. As technology continues to advance, we can expect this product to further evolve and contribute even more to the improvement of industrial production processes.

Product recommendations

Online message

Gongyi Shenlong Machinery Equipment Co., Ltd.

Tel:+86-13938265594

Tel:+86-18838087886

Wechat:008619339904886

E-mail:renchangjian@gyssljx.com

Add:412, 4th Floor, Shanghui Building Block B, Songshan Road No.16, Zijing Road Gongyi City, Zhengzhou City, Henan Province, China.

renchangjian@gyssljx.com

Looking forward to your letter

WhatsApp:+8618595836738

Online time:8:30-20:00

Wechat:008619339904886

Online time:8:30-20:00

Tel:+86 18838087886

Online time:8:30-20:00