Steel reinforcement is a fundamental material in construction, infrastructure, and industrial applications, forming the cornerstone of structural strength and durability. Steel reinforcement production lines are crucial for providing high-quality steel reinforcement, ensuring safety, reliability, and long-term performance. Understanding the factors that influence steel reinforcement production quality helps manufacturers optimize their processes and consistently produce superior products.

The quality of steel bars begins with the raw materials. Impurities, inconsistent chemical composition, or substandard iron can weaken the final product. Using premium iron ore and carefully controlled alloying elements ensures uniform strength, ductility, and corrosion resistance, forming the foundation of high-performance steel bars. Manufacturers focusing on raw materials for steel bar strength can significantly enhance final product quality.

The melting and refining stage directly determines the steel’s microstructure and mechanical properties. Advanced methods like Electric Arc Furnaces (EAF) and continuous casting reduce defects such as inclusions, porosity, and segregation. Precise temperature control during melting and refining is crucial for achieving homogeneity and desired mechanical strength. Adopting advanced techniques in steel bar melting and refining is key to consistent quality.

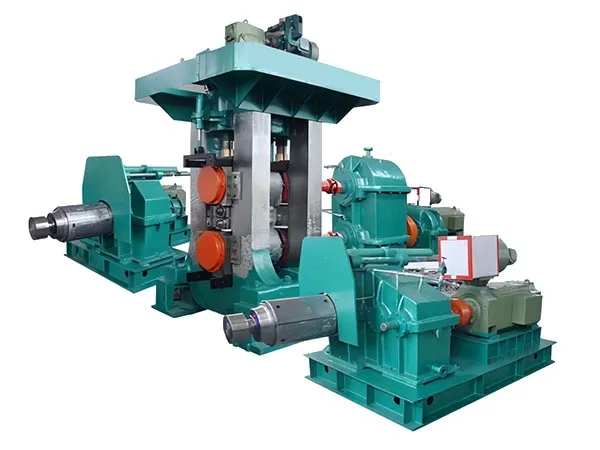

The rolling and forming process shapes the steel bars and affects surface quality, dimensional accuracy, and internal stresses. Variables such as rolling speed, temperature, and lubrication impact surface smoothness and mechanical performance. Optimizing these parameters minimizes cracks, deformations, and weak points in the final product. Learning how to improve steel bar quality in manufacturing often focuses on optimizing rolling and forming processes.

Heat treatment and cooling processes are vital for defining hardness, tensile strength, and flexibility. Uneven or rapid cooling can cause internal stresses or brittleness, while controlled quenching and tempering enhance mechanical properties. Consistent monitoring of cooling rates ensures uniform quality across all production batches. Effective heat treatment and cooling methods for steel bars are essential for achieving high-quality results.

Modern steel bar production depends heavily on precise machinery and automation. Poorly maintained equipment, worn-out rollers, or outdated control systems can compromise product quality. Investing in advanced technology, regular maintenance, and calibration ensures stable production and consistently high-quality steel bars. Manufacturers who prioritize maintaining machinery for consistent steel bar quality see significant improvements in output.

Production facility conditions—including temperature, humidity, and air quality—also influence steel bar quality. Excessive moisture or airborne contaminants can lead to oxidation or surface defects. Implementing environmental controls and protective measures minimizes these risks. Paying attention to environmental factors affecting steel bar production helps prevent defects and maintain integrity.

High-quality steel bars result from meticulous attention to raw materials, production techniques, machinery, and environmental conditions. Manufacturers who systematically address these factors can produce steel bars that meet international standards, enhance structural safety, and strengthen market competitiveness. Following best practices for high-quality steel bar production ensures superior performance and long-term reliability.

Rolling Mill Maintenance Guide: Maximize Performance, Extend Lifespan, and Reduce Downtime

2026-01-28How to Extend the Service Life of Rolling Mill Rolls: Practical Strategies for Steel, Aluminum, and Metal Rolling Plants

2026-01-23Comprehensive Guide to Rolling Mill Types and Their Production Processes

2026-01-15How to Improve Rolling Mill Production Efficiency: Practical Strategies for Higher Output and Better Quality

2026-01-09Address: Gongyi City, Zhengzhou City, Henan Province

E-mail: info@gyssljx.com

Phone: 0086 19339904886

If you have any product related questions, please feel free to call us at any time

With 30 years of professional experience, we customize efficient and energy-saving rolling mill production lines, providing you with one-stop service from design to installation and commissioning, helping you achieve steady growth in the steel industry.

Go

Top

SHENLONG Machinery · Your Rolling Equipment Expert ·