Cold rolling technology is an indispensable key process in modern metal manufacturing, playing a vital role particularly in automotive production, home appliance manufacturing, aerospace materials, and high-precision machinery industries. If you are new to metalworking or wish to deepen your understanding of cold rolling mill operations, this beginner's guide will help you fully grasp the core principles, workflow, and common misconceptions of the cold rolling process.

Cold rolling refers to a processing technique performed at room temperature, where immense pressure is applied through rolling mill rolls to reduce the thickness of metal sheets while enhancing surface quality. Unlike hot rolling, which requires high-temperature heating, cold rolling is conducted without heating. Consequently, the final products exhibit:

Higher dimensional accuracy

Superior surface finish

More uniform mechanical properties (strength, hardness, etc.)

Cold-rolled products are commonly used in:

Automotive bodies and structural components

Appliance housings

Precision mechanical parts

Manufacturing of strip steel, thin plates, and high-precision foils

Layman's terms: Cold rolling is like “using precision rollers to flatten dough,” making metal sheets thinner, straighter, and stronger.

1. Plastic Deformation of Metal Under High Pressure

Cold rolling mills typically consist of two high-strength rolls. As metal sheets pass through the roll gap, they undergo immense compressive stress, causing plastic deformation that achieves thinning and strengthening.

Roll Gap Compression: Material thickness is compressed as it passes through the roll gap.

Work Hardening: Internal grain deformation within the metal increases surface hardness and strength.

2. Precision Control of Roll Gap and Thickness (AGC Technology)

Roll gap is the core parameter affecting cold rolling quality.

Mechanical Gap Adjustment: Controlling sheet thickness by regulating the roll gap size.

Automatic Thickness Control (AGC): Modern cold rolling mills incorporate laser or X-ray thickness gauges that continuously monitor and fine-tune the gap, ensuring consistent product thickness.

3. Entry and Exit Tension Control

Maintaining proper tension prevents the following issues:

Material wrinkling

Sheet breakage

Thickness deviation

Surface scratches

Precise tension control systems ensure smooth, flat metal flow during rolling, enhancing finished product stability.

4. Lubrication and Cooling Systems

Lubricants and coolants play critical roles in cold rolling:

Reducing friction-induced heat

Preventing damage to roll and material surfaces

Improving surface finish

Extending equipment lifespan

Efficient lubrication and cooling systems also reduce energy consumption and boost production efficiency.

Cold-rolled materials achieve high precision due to the following characteristics of the process:

Precise control over sheet thickness

Advanced tension control and gap control systems

Material deformation occurs at room temperature, eliminating dimensional errors caused by thermal expansion

Surface treatment via lubrication and cooling systems results in superior surface finish

Consequently, cold-rolled products are highly suitable for industries demanding exceptional dimensional accuracy, flatness, and surface quality.

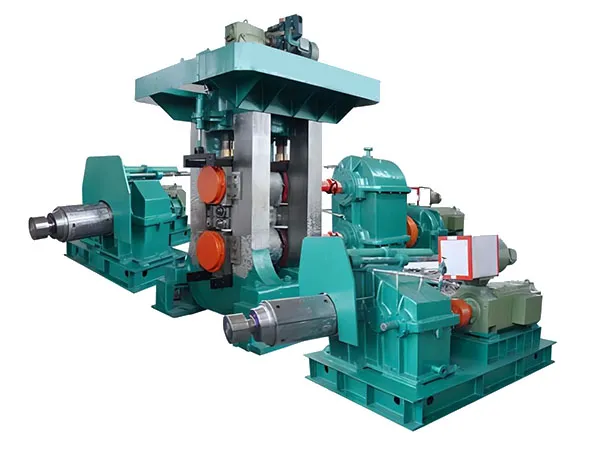

1. Four-High Mill

Comprising two working rolls and two backup rolls, it is suitable for medium-to-thick plate rolling, offering excellent rigidity and control capability.

2. Six-High Mill

Utilizes additional support rolls to significantly enhance flatness control, making it suitable for high-precision, ultra-thin sheet production.

3. Reversing Mill

Allows multiple passes of the sheet through the roll gap in both forward and reverse directions, enabling higher reduction rates. Ideal for small-to-medium batches of high-value-added products.

4. Tandem Mill

Multiple rolling stands connected in series enable high-speed continuous rolling, suitable for large-volume, high-efficiency production.

✔ Misconception 1: Cold rolling is merely simple thinning

Cold rolling involves multiple factors including material flow, stress distribution, work hardening, and lubrication, making it a highly complex process.

✔ Misconception 2: Thinner is always better

Excessive reduction can cause material cracking, deformation, or reduced mechanical properties.

✔ Misconception 3: Neglecting lubrication and cooling

Poor lubrication increases friction, scratches surfaces, and may damage rolls.

✔ Misconception 4: All materials require identical parameters

Different metals exhibit varying ductility, necessitating customized reduction rates and tension control.

Mastering the structure, operational mechanisms, and key control technologies of cold rolling mills not only helps engineers optimize production processes but also assists procurement personnel in selecting more suitable equipment. For beginners, understanding cold rolling isn't difficult. By grasping the four core elements—pressure, roll gap, tension, and lubrication—one can quickly get started with the cold rolling process.

Rolling Mill Maintenance Guide: Maximize Performance, Extend Lifespan, and Reduce Downtime

2026-01-28How to Extend the Service Life of Rolling Mill Rolls: Practical Strategies for Steel, Aluminum, and Metal Rolling Plants

2026-01-23Comprehensive Guide to Rolling Mill Types and Their Production Processes

2026-01-15How to Improve Rolling Mill Production Efficiency: Practical Strategies for Higher Output and Better Quality

2026-01-09Address: Gongyi City, Zhengzhou City, Henan Province

E-mail: info@gyssljx.com

Phone: 0086 19339904886

If you have any product related questions, please feel free to call us at any time

With 30 years of professional experience, we customize efficient and energy-saving rolling mill production lines, providing you with one-stop service from design to installation and commissioning, helping you achieve steady growth in the steel industry.

Go

Top

SHENLONG Machinery · Your Rolling Equipment Expert ·