Cold-rolled steel coils and cold-rolled aluminum coils are indispensable basic materials in modern manufacturing. With their high dimensional accuracy, excellent surface quality, and stable mechanical properties, cold-rolled coils are widely used in automotive manufacturing, home appliances, construction, machining, and high-end industrial fields.

For steel mills, aluminum plants, and equipment purchasers, a thorough understanding of the cold rolling process flow not only helps optimize production efficiency but also enables more informed decisions regarding equipment selection, quality control, and cost management.

This article will systematically analyze the complete process of a cold-rolling production line, from raw material preparation to finished coil delivery, helping readers fully understand the core logic and key control points of the cold rolling process.

The cold rolling process is a complex, multi-step process that transforms hot-rolled steel coils (usually raw materials) into finished cold-rolled coils with superior dimensional accuracy, surface quality, and mechanical properties.

Process flow diagram: Pickling → Cold Rolling → Annealing → Skin Pass/Tension Leveling → Coiling

Each process directly affects the surface condition, thickness accuracy, and mechanical properties of the final cold-rolled coil. The core steps of the cold rolling process will be broken down below.

State: Raw steel coil, typically produced by hot-rolled strip mills.

Characteristics: Relatively thick (e.g., 2.0 mm to 8.0 mm), with a surface covered by a hard, brittle substance called iron oxide scale (or rolling oxide). Iron oxide scale is formed by the reaction of iron with oxygen during high-temperature rolling.

Applications: Iron oxide scale must be removed, otherwise it will damage the cold-rolled roll surface and reduce the surface quality of the finished steel.

Why is pickling crucial?

To remove scale and rust formed during hot rolling

To improve the material's ductility during cold rolling

To provide clean and stable surface conditions for subsequent rolling

Pickled coils have a smooth and clean surface, which is fundamental to the production of high-quality cold-rolled coils.

Process Description:

Uncoiling and Preparation: Hot-rolled steel coils are uncoiled, and the ends are sheared and welded to form a continuous strip, ensuring the continuous operation of the pickling line.

Pickling Tanks: The strip passes through multiple tanks filled with acid (usually hydrochloric acid). The acid reacts with the iron oxide scale, dissolving and removing it.

Rinsing and Drying: After pickling, the strip must be thoroughly rinsed with clean water or high-pressure water to remove residual acid and iron salts to prevent secondary corrosion, and then dried.

Product: Pickled coil. The surface is clean, making it a qualified cold-rolled raw material.

Purpose: To apply immense pressure to strip steel at room temperature (below the recrystallization temperature) to reduce its thickness to a target dimension (e.g., 0.3 mm to 3.0 mm), while simultaneously improving surface finish, dimensional accuracy, and strip shape.

Process Description:

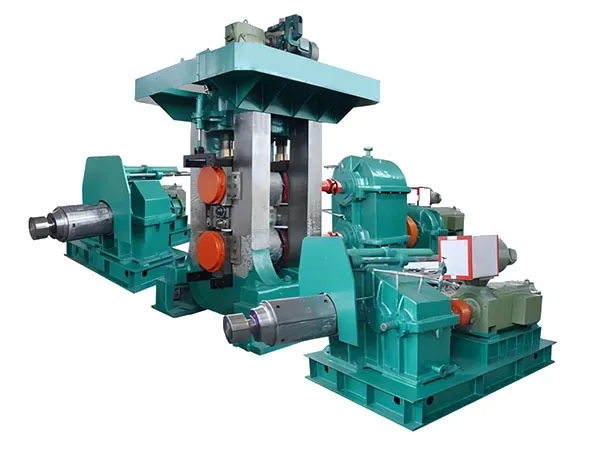

Cold Rolling Mill Type: Typically uses a four-high or six-high reversible mill (where the strip reciprocates through the mill) or a five-stand continuous mill (high-speed continuous rolling).

Rolling Principle: The work rolls directly contact the strip steel and apply pressure; the support rolls support the work rolls to prevent bending and deformation.

Lubrication and Cooling: During rolling, an emulsion (a mixture of water and rolling oil) is continuously sprayed to lubricate the rolls and strip steel and remove the significant frictional heat.

Results: The steel undergoes work hardening. The grains are elongated along the rolling direction, generating numerous dislocations and internal stresses. This increases the strength and hardness of the steel, but significantly reduces its plasticity (ductility), resulting in a Full Hard Coil.

Purpose: To thoroughly remove residual rolling emulsion (rolling oil) from the surface of the Full Hard Coil.

Importance: If rolling oil remains, it will decompose into carbon black during the subsequent high-temperature annealing process, contaminating the steel surface and affecting the final product quality.

Process Description: The strip steel is continuously cleaned, rinsed, and dried using chemical cleaning agents (such as alkaline solutions) in conjunction with electrolysis and brushing.

Purpose: To eliminate the internal stress caused by cold rolling work hardening, allowing distorted grains to recrystallize, thereby restoring the steel's plasticity (ductility) and toughness, and adjusting its mechanical properties to meet customer requirements.

Process Description:

Annealing Temperature: Heating to above the steel's recrystallization temperature and holding for a period of time.

Types:

Batch Annealing (CA): Steel coils are stacked and slowly heated and cooled in a protective atmosphere (usually a hydrogen-nitrogen mixture). Long cycle time, but excellent performance for certain steel grades (such as deep-drawing steel).

Continuous Annealing (CAL): Strip steel passes continuously at high speed through a long heating furnace, soaking zone, and cooling zone. Short cycle time, high production efficiency, and good product uniformity.

Protective Atmosphere: Protective gases (such as nitrogen and hydrogen) must be used to prevent oxidation of the steel at high temperatures.

Result: The steel recovers to a soft state and has good deep-drawing properties.

Purpose:

Improving Strip Shape: Eliminating unevenness defects such as wavy edges and warping that may occur in the strip during annealing, making the strip straighter.

Surface Roughness Control: Using rolls with specific textures, the surface roughness of the steel is adjusted to facilitate subsequent coating (e.g., automotive sheet).

Yield Plateau Elimination: Eliminating yielding after annealing improves the deep-drawing performance of the steel.

Process Description: A slight cold rolling process. The thinning rate is very small (typically 0.4% to 3%), primarily for shaping and changing the surface condition, not for reducing thickness.

Purpose: To provide final processing and protection for the product, ensuring it meets finished product requirements and facilitates transportation.

Process Description:

Edge Trimming: Trimming the edges of the strip to ensure width accuracy and edge neatness.

Electrostatic Oiling: Applying a thin layer of anti-rust oil to the surface of the finished strip to prevent rusting during storage and transportation.

Slitting: Cutting large coils into smaller coils according to customer-specified width and weight (or length).

Inspection and Packaging: Strictly inspect the surface quality and dimensional accuracy, and finally pack it for moisture protection and impact protection.

After completing the entire cold rolling process, the finished coils possess the following advantages:

Excellent Surface Quality: Smooth and clean, low defect rate

High Dimensional Accuracy: Uniform thickness, stable shape

Wide Applications: Automotive manufacturing, appliance housings, architectural decoration, industrial components, etc.

High-quality cold-rolled coils provide a reliable guarantee for downstream deep processing.

Conclusion: Understanding Cold Rolling Processes Enhances Manufacturing Competitiveness

A comprehensive understanding of the cold rolling process not only helps steel and aluminum mills optimize production management and improve product quality, but also helps purchasing parties and engineering technicians better evaluate equipment and material solutions.

From pickling to the final finished coil, each process determines the ultimate value of cold-rolled products. A scientific and stable cold rolling process is the key foundation for achieving high-end manufacturing.

Rolling Mill Maintenance Guide: Maximize Performance, Extend Lifespan, and Reduce Downtime

2026-01-28How to Extend the Service Life of Rolling Mill Rolls: Practical Strategies for Steel, Aluminum, and Metal Rolling Plants

2026-01-23Comprehensive Guide to Rolling Mill Types and Their Production Processes

2026-01-15How to Improve Rolling Mill Production Efficiency: Practical Strategies for Higher Output and Better Quality

2026-01-09Address: Gongyi City, Zhengzhou City, Henan Province

E-mail: info@gyssljx.com

Phone: 0086 19339904886

If you have any product related questions, please feel free to call us at any time

With 30 years of professional experience, we customize efficient and energy-saving rolling mill production lines, providing you with one-stop service from design to installation and commissioning, helping you achieve steady growth in the steel industry.

Go

Top

SHENLONG Machinery · Your Rolling Equipment Expert ·