A rolling mill works on the principle of plastic deformation, where a metal workpiece is passed between one or more pairs of rotating cylindrical rollers. The primary purpose is to reduce the thickness and/or change the cross-sectional shape of the metal.

The basic working principle involves reducing the thickness or changing the cross-sectional shape of a workpiece. Here's a breakdown of how it works:

Deformation: When metal passes between two rotating rolls, compressive forces are applied. These forces cause the metal to deform plasticly, meaning its shape changes permanently without fracturing.

Reduction: The gap between the rolls is smaller than the incoming thickness of the metal. As the metal passes through, its thickness is reduced, and its length increases to maintain a constant volume.

Speed Difference: The rolls rotate at a certain speed, and there's a slight difference in speed between the surface of the roll and the metal. This difference helps to pull the metal through and contributes to the deformation.

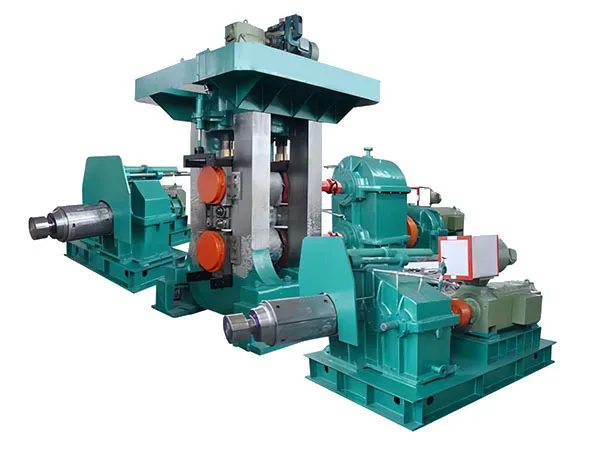

Rolls: These are the heart of the rolling mill. They are heavy, cylindrical tools made from specialized steel.

Work Rolls: These are the rolls that directly contact the metal.

Backup Rolls: In some mills (like four-high or cluster mills), larger backup rolls support the work rolls to prevent them from bending under the immense pressure, ensuring uniform thickness.

Roll Stands: These sturdy housings hold the rolls and bearings in place.

Drive System: Powerful motors and gearboxes provide the rotational force to turn the rolls.

Screw-down Mechanism: This system adjusts the gap between the rolls, controlling the final thickness of the rolled product. It can be hydraulic or electromechanical.

Entry and Delivery Guides: These guide the metal precisely into and out of the roll gap.

Cooling and Lubrication Systems: These are crucial for managing heat generated during rolling and reducing friction between the rolls and the metal.

Hot Rolling: This occurs above the metal's recrystallization temperature. It allows for large deformations with relatively low force and is ideal for producing large quantities of relatively inexpensive products like structural steel. The metal is more ductile and easier to shape.

Cold Rolling: This occurs below the metal's recrystallization temperature, often at room temperature. It produces metal with a smoother surface finish, tighter tolerances, and increased strength and hardness due to strain hardening. However, it requires more force and the metal becomes less ductile.

Rolling mills are essential in many industries for producing a wide range of metal products, including:

Sheets and Plates: Used in construction, automotive, and appliance manufacturing.

Strips and Foils: Used in packaging, electronics, and various other applications.

Structural Shapes: Beams, channels, and angles for buildings and infrastructure.

Bars and Rods: Used in machining, forging, and as raw material for other products.

Rails: For railway tracks.

In essence, a rolling mill works by precisely squeezing and stretching metal between rotating rolls, transforming its shape and properties to meet specific industrial requirements.

Rolling Mill Maintenance Guide: Maximize Performance, Extend Lifespan, and Reduce Downtime

2026-01-28How to Extend the Service Life of Rolling Mill Rolls: Practical Strategies for Steel, Aluminum, and Metal Rolling Plants

2026-01-23Comprehensive Guide to Rolling Mill Types and Their Production Processes

2026-01-15How to Improve Rolling Mill Production Efficiency: Practical Strategies for Higher Output and Better Quality

2026-01-09Address: Gongyi City, Zhengzhou City, Henan Province

E-mail: info@gyssljx.com

Phone: 0086 19339904886

If you have any product related questions, please feel free to call us at any time

With 30 years of professional experience, we customize efficient and energy-saving rolling mill production lines, providing you with one-stop service from design to installation and commissioning, helping you achieve steady growth in the steel industry.

Go

Top

SHENLONG Machinery · Your Rolling Equipment Expert ·